20 years of craftsmanship | Revealing how deep-sea iron plates are "bite-resistant and paint-resistant" - Thorforce's entire process of custom fishing gear production

Why do global fishing gear brands choose us for OEM? The answer is hidden in the details of the production line

1. The "resistance" secret of deep-sea iron plates: coating technology is the soul

"Last week, I caught a 100-kilogram GT, and the iron plate was bitten all over, but the coating didn't fall off at all!" - This is the most common experience reported by Thorforce's cooperative customers.

As the "hidden champion" in the field of fishing gear OEM, we know that 60% of the combat effectiveness of deep-sea iron plates (jigging) depends on the coating process. Especially for beast-level opponents such as tuna, GT, and marlin, ordinary spray paint can't withstand a few rounds.

Thorforce's solution:

Three-layer armor process:

Bottom thermal transfer: Use high temperature to "brand" the hot stamping sticker on the surface of the iron plate

Luminous UV spraying: Workers hold spray guns to draw gradient effects and superimpose luminous/fluorescent paints.

Diamond coating: varnish is baked and cured to form a protective layer

Violent quality inspection method:

Quality inspectors extract 2% of jigging and scrape with a utility knife

Use a magnifying glass to check bubbles or impurities in the full inspection process

Second, ODM/OEM core advantages: Your needs can be mass-produced in 3 steps

"From drawings to containers, delivery in as fast as 30 days" - this is not an advertisement, but the daily routine of Thorforce's flexible supply chain.

STEP 1: Design stage

Material selection: lead (the king of cost-effectiveness), zinc alloy (environmental compliance), tungsten steel (fast sinking artifact)

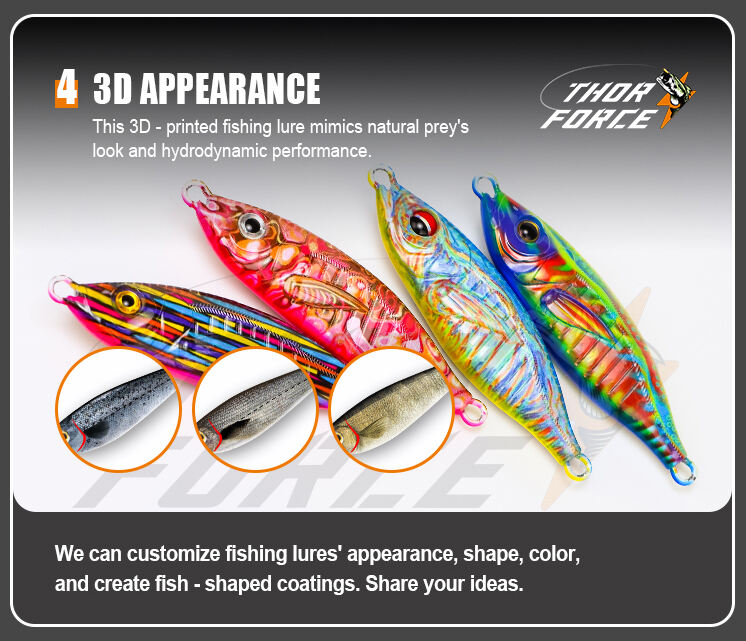

3D modeling: 12 preset textures such as fish scales/bionic blood vessels are provided, and customization of drawings is supported

Fish eyes: hand-inlaid 3D fish eyes with luminous light, fixed with special glue, tensile test ≥20kg

STEP 2: Production stage

Full-process MES monitoring: Each iron plate has an "electronic ID card" to query the production progress and quality inspection links online

Free combination of accessories: three hooks/auxiliary hooks/swivel rings, accurately matched according to the target fish species (GT must select stainless steel reinforcement rings)

STEP 3: Quality control delivery

Simulated actual combat test: tie the iron plate to the motor and hit the reef 500 times continuously to imitate the seabed scratch

Anti-rust black box experiment: 72-hour test in a salt spray chamber

3. Why do you say we are a "brand plug-in"?

Case 1:

American customer Mike wants to develop a "squid color iron plate", but the UV printing effect on the market is too fake. We formulated a bioluminescent paint that still maintains the color difference of attracting fish at a depth of 30 meters, and the repurchase rate of the first batch of orders is 83%.

Case 2:

A Japanese brand commissioned the production of a 500g ultra-heavy iron plate, and traditional molds are easy to deform. We use tungsten steel CNC engraving + vacuum coating, and the yield rate has increased from 67% to 98%, and the production cost has been reduced by 15%.

4. Cooperation threshold? It does not exist!

Minimum order quantity: 200 pieces for hard baits and 2,000 pieces for soft baits (mixed colors and mixed packaging are also OK)

Proofing cycle: 3 days for 3D drawings, 7 days for sample delivery (mold products)

Exclusive service: Each customer is assigned a product manager + QC for follow-up, and 24-hour response to production issues

Written in the end:

For 20 years, we have only focused on one thing - making every gram of lead a deadly weapon on the seabed. From South African swordfish to Alaskan king salmon, Thorforce iron plates are setting off a "precision hunting" revolution in 36 countries.

Now, it's your brand's turn.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

CY

CY

MK

MK

KA

KA